The plan seeks to reduce Volvo Cars’ expenditure by SEK 18 billion ($1.8 billion), with this first wave of redundancies primarily impacting Swedish employees. Further restructuring and job losses are expected elsewhere as the carmaker conducts an internal strategic review.

Volvo Cars has begun enacting its recently launched cost and cash action plan which seeks to reduce the carmaker’s cost base by $1.8bn per year. The first steps of this plan involve a shrinkage in Volvo’s office workforce, with approximately 3,000 positions expected to be lost.

The company reports that, of this number, 1,200 positions at the Swedish branch of Volvo (Volvo Personvagnar AB) will be made redundant. 1,000 consultant positions will also be lost, with the majority also being in Sweden. These losses follow an earlier 5% reduction in staff numbers at its Ridgeland, South Carolina, US plant in May, with 125 roles being terminated.

The cost and cash action plan may result in further redundancies, as Volvo is currently conducting an organisation-wide strategic review which will help its management decide on further restructuring action. The carmaker reports that it expects all structural changes that result from the review to be completed by Q3 2025.

Håkan Samuelsson, Volvo Cars president and CEO, commented that the workforce reductions were “difficult decisions” to make, but are vital to making the Gothenburg-based OEM “stronger and even more resilient”. Samuelsonn pointed to the changing landscape of the automotive industry as a reason for Volvo to become leaner and more efficient. He described the industry as being in a “challenging period” that requires better cash flow generation and lower costs, and added: “At the same time, we will continue to ensure the development of the talent we need for our ambitious future.”

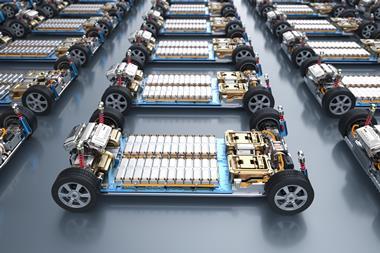

In the announcement, Volvo Cars also reaffirmed its commitment to EVs, “as fully electric is the fastest growing market segment”. In the last two months, it has started European production of its EX30 electric SUV at its Ghent plant, as well as revealed a new extended-range plug-in hybrid SUV designed specifically for the Chinese market, the XC70. Former head of procurement and supply chain at Volvo Cars, Kerstin Enochsson, previously explained the steps taken to integrate this transition throughout the value chain, with the carmaker introducing ”quite a few direct contracts with upstream players that we haven’t have before”. ”Our trajectory is super positive,” she commented, adding that the company aims to have 50% of the vehicles it sells be BEVs by 2025, and 100% by 2030.

With this commitment to an EV transition, resiliency in the battery supply chain is paramount to success. Find out more on how the European EV market has reacted to recent pressures:

Europe’s EV forecast has dropped – and here’s what it means for the supply chain

Topics

- Companies

- Countries

- Electric Vehicles

- Europe

- EV & Battery Production

- Finished Vehicle Logistics

- Inbound Logistics

- Lean Logistics

- Lean Transformation

- Logistics Management

- News

- News and Features

- OEMs

- Region

- Supply Chain Focus

- Supply Chain Optimisation

- Supply Chain Planning

- Sustainability

- Sustainable Supply Chain Design

- Sweden

- Topics

- Volvo Cars

No comments yet